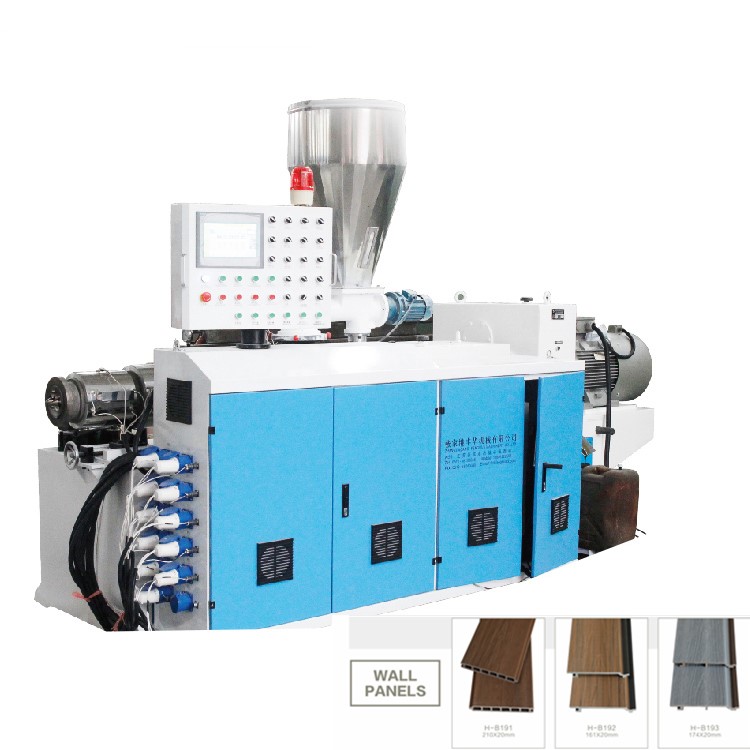

PP PE WPC Profile Extrusion Machine

- FUNGWAH

- Jiangsu,China

- 45 Days

- 10 Sets/Month

pp pe wpc plastic machine is a thick plate extrusion line newly developed by our company to absorb and digest foreign advanced technology and technology. It is mainly used to produce wood-plastic floor panels. The thickness of the panel can be 5-15mm, and the width of the panel can be 100-300mm. .

Door WPC PP Pe PC Hollow Sheet Panel Twin Screw Profile Extruder Machine Extrusion Line

| Item | component | quantity |

| 1. | double screw extruder | 1set |

| 2. | mould | whole 1set |

| 3. | vacuum calibration tank | 1set |

| 4. | hauling machine | 1set |

| 5. | cutter | 1set |

| 6. | stacker | 1set |

detail descriptions;

1. extruder specification

Model | YF180 | YF240 | YF300 | YF400 | YF500 | YF600 |

Max. width of product(mm) | 180 | 240 | 300 | 400 | 500 | 600 |

Extruder model | SJSZ55/110 | SJSZ65/132 | SJSZ65/132 | SJSZ65/132 | SJSZ80/156 | SJZ80/156 |

Max. extrusion capacity(kg/h) | 150 | 250 | 250 | 250 | 360 | 360 |

Extruder power(kw) | 22 | 30/37 | 30/37 | 30/37 | 55 | 55 |

Cooling water(M3/h) | 5 | 7 | 7 | 8 | 10 | 12 |

Compressed air(M3/min) | 0.2 | 0.3 | 0.3 | 0.3 | 0.4 | 0.5 |

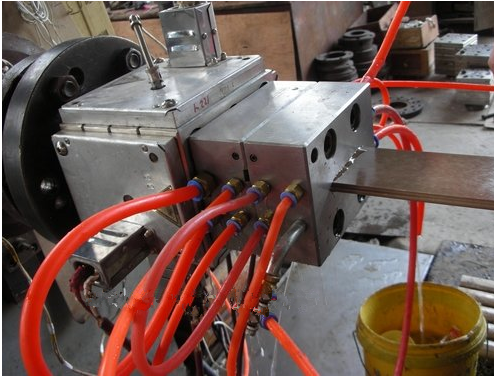

Mold part for pvc door and window profile extrusion line

Vacuum calibration table for pvc door and window profile extrusion line

Hauling machine for pvc door and window profile extrusion line

Other auxiliary machine in pvc door and window profile extrusion line

Final product reference

ZHANGJIAGANG FUNGWAH MACHINERY CO.,LTD

The company was established in April 1995,is located in jiangsu zhangs' port,mainly engaged in plastic extrusion machine, washing recycling line, plastic crusher,pipe productionline, production line and other plastics research and development, production, sales andother business. Enterprise strength strong, strong technical force, strict grasp the production quality, at the same time uphold the operating principle of goodfaith. Operatedby reliable product quality, reasonable price, well received by customers, has many longterm partner. To use platform to make a man of insight for a better future.

Today the quality of tomorrow' s market. Start now!L ook to the future! With person whowith breadth of vision to create plastic industry tomorrow.

1 Q: Why choose us?

A: Fenghua machinery is specialized for the products with long time experience. We always

pay attention to the quality of equipment we manufactured, and we have sufficient team

which can go to customer factory in very short time when it's required. And so far we have

installed machines at most hot spot region around the world, the stable running of

machines are the best explanation. Welcome contact us to know reference customer near to

2 Q: How long the machine can be delivered?

A: Generally we have the semi-ready machines or even ready machine at store, so the deliv-

ery time is very fast, normally around 30 40days,depending on the kinds of machines and

the quality of machines you will order.

3 Q: How to install the machines?

A: Upon customer's requirement,we can send technician to customer's factory for installation

and training. So the Chinese technician will install machines, teach local workers about

machine installation and operations and so on.

4 Q: What kind payment terms?

A: We can accept multiple kind payment terms,like T/T, LC,ETC.

5 Q: What's the warranty?

A: One year since installation completed. In the warranty period, in case any parts broken by

uncontrolled factor, we will be responsible and send the parts immediately by courier or air

cargo.