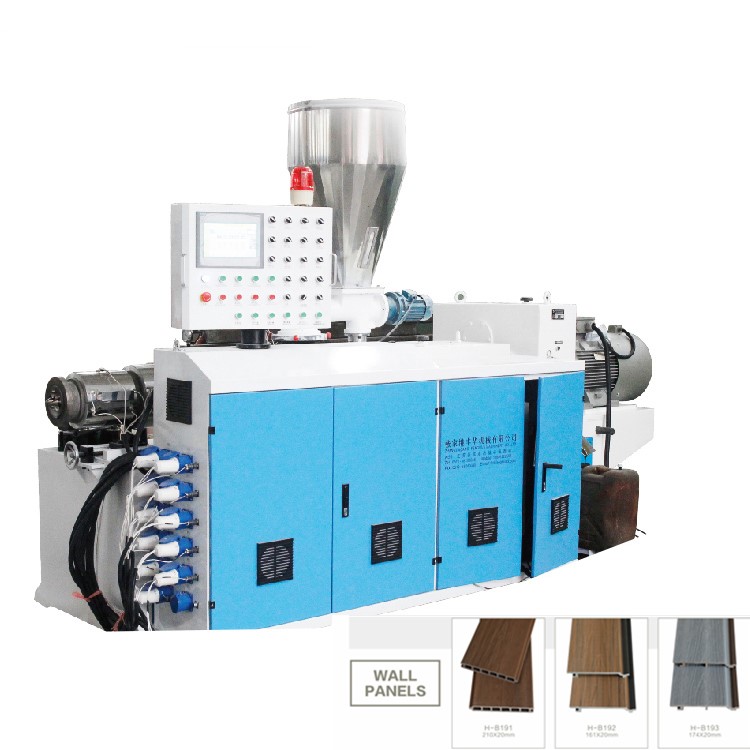

WPC Decking Profile Production Machine

- FUNGWAH

- Jiangsu,China

- 45 Days

- 10 Sets/Month

Application: Sheet, Profile, Plates

Plastic Processed: WPC

Condition: New

Screw Design: Double-screw

Twin Screw Type: Counter-rotating conical Twin-screw

Screw diameter (mm): 132 mm

Screw L/D Ratio: 33:1

Screw Speed (rpm): 110 rpm

Product Description

WPC Decking Profile Production Machine

Hot sales

| Item | component | quantity |

| 1. | double screw extruder | 1set |

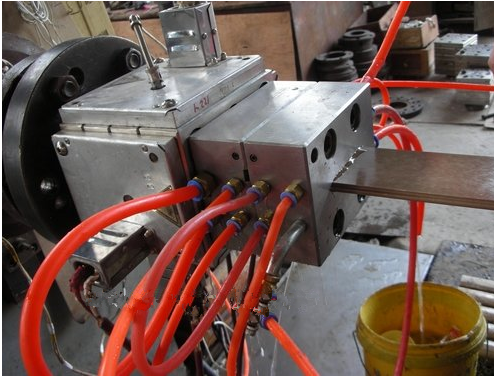

| 2. | mould | whole 1set |

| 3. | vacuum calibration tank | 1set |

| 4. | hauling machine | 1set |

| 5. | cutter | 1set |

| 6. | stacker | 1set |

detail descriptions;

1. extruder specification

Model | YF180 | YF240 | YF300 | YF400 | YF500 | YF600 |

Max. width of product(mm) | 180 | 240 | 300 | 400 | 500 | 600 |

Extruder model | SJSZ55/110 | SJSZ65/132 | SJSZ65/132 | SJSZ65/132 | SJSZ80/156 | SJZ80/156 |

Max. extrusion capacity(kg/h) | 150 | 250 | 250 | 250 | 360 | 360 |

Extruder power(kw) | 22 | 30/37 | 30/37 | 30/37 | 55 | 55 |

Cooling water(M3/h) | 5 | 7 | 7 | 8 | 10 | 12 |

Compressed air(M3/min) | 0.2 | 0.3 | 0.3 | 0.3 | 0.4 | 0.5 |

- Extruder adopts WPCd dedeciated screw, make sure best plastisizing effect, furhter make sure best final product shape

- Extruder speed and haul off speed controlled by ABB frequency inverter, saving power and easy adjusting speed

- Extruder temperature adopt PID control, temperature fluctuation self adjusting, it realise the high automatic level

- Equipped with infrared tracking device which can elimintate the problem of fluctuation of extrusion flow rate, further can make sure get best product

- Lower power consumption, it can save 25-30% electrical power consumption comparing with most same kind PVC ceiling extruder.

- Economical price, suitable for large scale investment.

Mold part for pvc door and window profile extrusion line

Vacuum calibration table for pvc door and window profile extrusion line

Hauling machine for pvc door and window profile extrusion line

Other auxiliary machine in pvc door and window profile extrusion line

Any question about WPC Decking Profile Production Machine, please feel free to contact us ,

we are pleased to recommend suitable scheme and production configuration for you specially!